|

Brief Description of Company

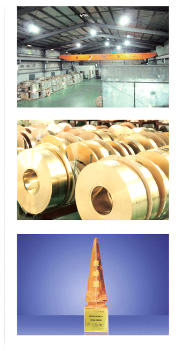

Guo Ching Precision Co., Ltd. (GCP) was founded in 1987 and has ever since been committed to its business. The first slitting plant which received ISO-9001 certification in northern Taiwan, GCP is a professional copper alloy dealer and a large-sized copper material precision cutter - cutting ability: 650mm slitting, thickness 0.05mm - 3.0mm, thickness 2.0mm - 650mm, tolerance ± 0.05mm. Width tolerance and bend radii both can meet clients' requirements. Achieving prominence in the industry step by step, every step signifies the track of our growth and strength.

Industrial electronic elements today all tend to be light-weight and compact, high-precision, high-quality. From aviation products, semiconductors, ICs, 3C appliance terminals, connectors to medical machines to aeronautical science, basic copper alloy materials have been innovated as technology advances. Demand for the raw materials will continue to rise, so it can be expected that the copper alloy material industry will definitely grow nonstop in the future. In a market that is increasingly international and free, GCP always remains highly vigilant and seeks breakthroughs, innovation, excellence and competitiveness, with the aim to meet the requirements of technological innovation, clients' needs and offering quality service.

|

|

|

Corporate Information

Business Philosophy:

Honesty, attentive, and innovative technology at hearts,

Implement satisfactory quality for a substantial business.

Management Philosophy: People focused, Value-oriented

Service Policy: Touch your heart

Quality Policy: Professionalism / Good Faith / Quality / Service |

|

|

Company History

| 1987.12 |

Register as Dahua Co., Ltd., capital NT$1 million |

| 1991.11 |

Renamed Guo Ching Hardware Co., Ltd. |

| 2002.10 |

Relocated to Linkou to expand operations |

| 2002.12 |

Acted as agent for Japan-based Mitsubishi's special copper alloys |

| 2003.04 |

ISO-9001-certified |

| 2003.11 |

Renamed Guo Ching Precision Co., Ltd. |

| 2004.10 |

Won the Award for Outstanding Small- and Medium-sized Enterprise in Innovation and R&D |

| 2007.06 |

Won the 11th Golden Peak Award for Outstanding Enterprise of the year. |

| 2012.07 |

Capital increased to NT$70 million |

| 2014.04 |

Registered the CU-01 trade mark |

| 2016.01 |

Implement high-speed laser welding machine, to increase output performance of production |

| 2017.03 |

Co-develop special raw materials for applications with famous brands of ASUS, ACER, COMPAL, PEGATRON, DELTA ELECTRONICS |

| 2018.05 |

Received the "Excellent Award" from CTS COMPONENTS TAIWAN, LTD. |

|

Quality Assurance

| Product Quality Planning |

Meets customer requirement, meets CNS, JIS, GB specifications |

| Incoming Material Control |

Product incoming materials inspection control |

| Production Control |

Regular inspection during production

(Basic principle is to assure no outflow of nonconforming products,

no inferior production, and no acceptance of defects) |

| Packaging Control |

Satisfy customer requirement, customized packaging |

| Shipment Control |

Quality inspection before shipment (rigorous OQC inspection and records) |

| After Service |

Personal account and professional perfect service |

| Environmental Friendliness |

Meets RoHS standards, and Sony green partner |

| ISO Approval |

ISO 9001 approved enterprise |

|

| Large Pulling Force Tester |

AKASHI Hardness Tester |

Conductivity Tester |

|

|

|

|

|

Company Results

|

|

|

| ISO 9001:2008 |

11th Golden Peak Award |

Innovation and R&D Award |

|

|

|

|